The sewing machine roller foot is going to save you from many headaches. Have you worked with tricky fabric like knits, vinyl, or faux leather? They can slip around making your sewing experience less than fun.

WHAT DOES THE ROLLER FOOT LOOK LIKE?

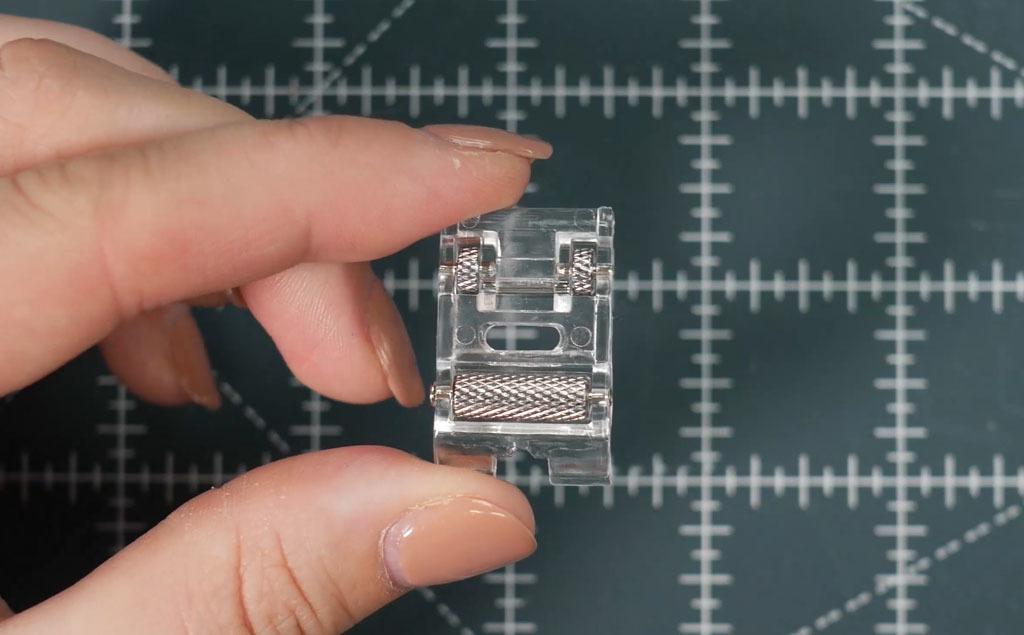

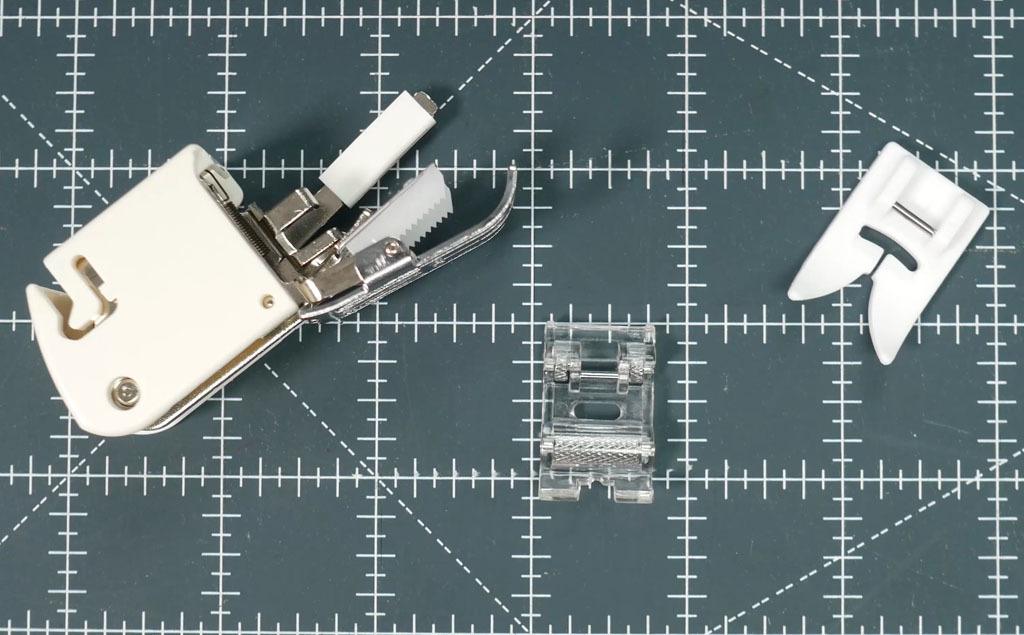

The roller foot has little cylinders on the bottom of the foot that rotate as you sew. Because the fabric is being fed from both the top (the cylinders) and the bottom (the feed dogs), the layers of fabric stay together and avoid slippage. If you’ve ever sewn fabric that moves on you, you know this is a big deal. Another cool feature that the roller foot has is a larger opening where the sewing machine needle goes into the fabric. This will allow you to not only use a straight stitch, but you can use zig-zag or decorative stitches as well. Also, there is a little cutout on the front of the foot. This is convenient, if you are sewing rick rack or ribbon, as you have more visibility.

OTHER PRESSER FEET THAT ALSO HELP WITH TRICKY FABRIC

You may have heard a similar description for another foot - the walking foot. The walking foot has built-in feed dogs that grip your fabric for better control. The walking foot has a little arm that goes over the needle clamp screw. Sometimes, your machine’s screw is too short and you are unable to use a walking foot. If that is the case, the sewing machine roller foot is a great alternative option since it has those cylinders that work in a similar way as the walking foot feed dogs.

Another presser foot that works well with vinyl and faux leather is the non stick foot.

You may be thinking to yourself, walking foot, roller foot, non stick foot- which one do I use?

Well, you will often find that several different feet can be used to produce the same results, but you will also find that certain feet work better for you in different scenarios. Also, you will have a preference.

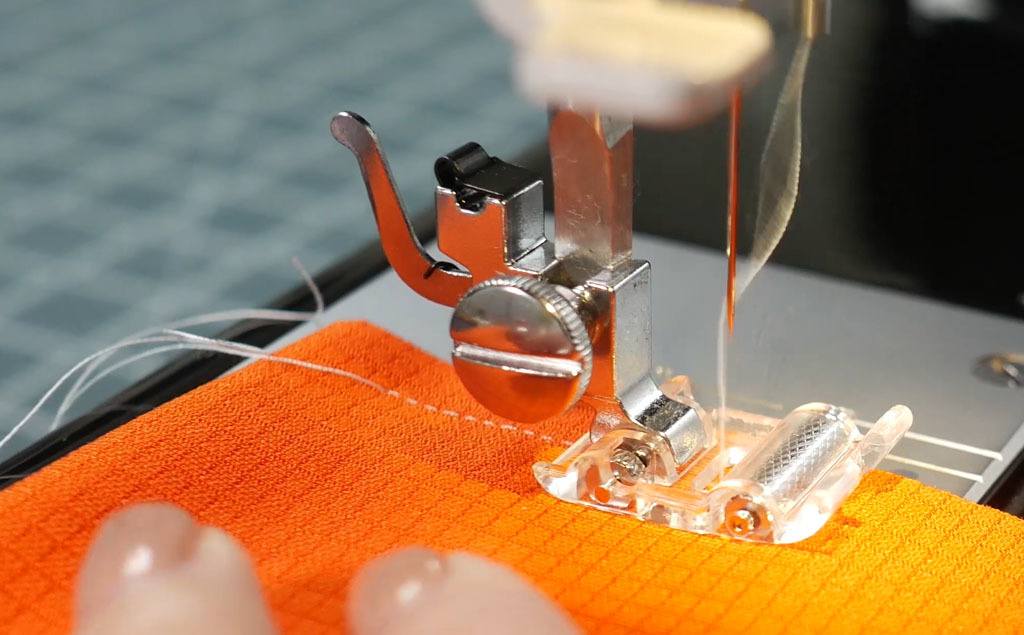

An example, the roller foot can be used with hard to feed material like jersey and knitted fabric.

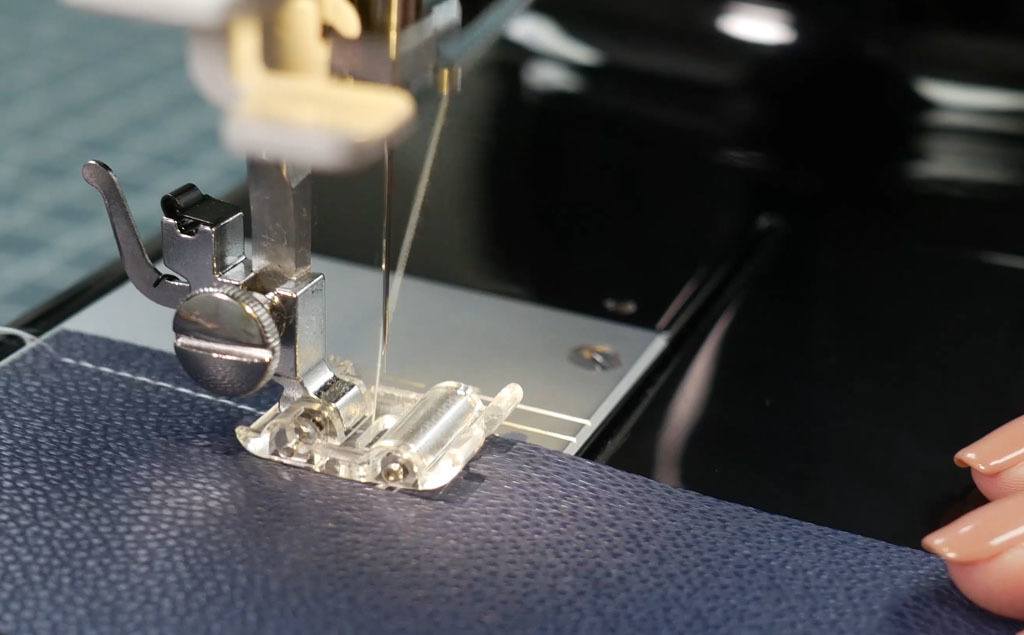

Although it is great for this use, I almost exclusively use a walking foot when I sew knits. This is because I have found those setting on my machine that just works really well when using the walking foot. I get really good results. Kind of a "don’t fix if it ain't broken." Then there’s another side of me that says, use it, test it, try it, because you don't know until you try. Another example, the nonstick foot work great for leather and vinyl and I have enjoyed using it in that application; however, in trying the roller foot, I think I like the roller foot better for the leather. I never thought I would say that! Personally, I still like the non stick foot when sewing vinyl, but the roller foot does work well with it too.

IS THE ROLLER FOOT BEST FOR MY PROJECT?

I find it really helpful to test on scraps, see which option works best for what you are working on. One thing to remember, when working with materials like faux leather and vinyl, make sure that you increase your stitch length. If your stitches are too close together, you will perforate the fabric and it can easily tear at the seam. You don't want to do that!

CONCLUSION

I hope that this saves you frustration when dealing with slippery fabric. Until next time, Happy Sewing, Everybody!